Easy

Process:

When I first built my Pull-Behind Lawn Roller I didn't have a lathe yet so I just hacked something together for closing up the hole in my lawn roller. However, it was always leaking and I've wanted to do something more permanently so I took a chunk of metal, turned, faced, bored and threaded a 12 pitch thread on the inside of the ring. After that, I took a chunk of 2.500" aluminum I had cast with my Home Foundry a while back, cut off a piece on my Metal Band Saw, turned and knurled the outside, then turned the other half to size and threaded it to a matching 12 pitch thread.

The only thing that was left to do is weld the outside ring to my lawn roller, slip an o-ring on the cap and screw it on. This was more of a "would be nice to have" project and not so much a "really need this" project so I did enjoy making it

Videos:

Pictures:

|

| The 2.75" ring with a 12 TPI female thread |

|

| The cap made out of aluminum with a matching 12 TPI male thread |

|

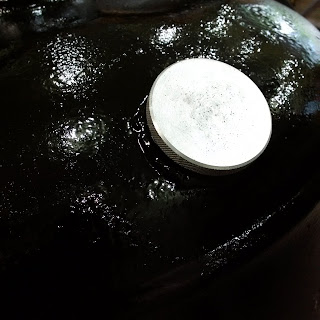

| Another view of the aluminum cap |

|

| The cap with the o-ring installed |

|

| The o-ring kit I bought at princess auto or harbor freight, I can't remember which one it was |

|

| Grinding off some of the tar in preparation for welding |

|

| After the ring was welded to the lawn roller |

|

| Another view |

|

| Test fitting the cap before applying some more asphalt spray |

|

| After the asphalt was sprayed on |

|

| The installed cap |

|

| Another view |

Metal lathe & accessories

Metal band saw

MIG welder

Angle grinder

Ear muffs & safety goggles

Materials:

1/2" of 2.500" diameter metal

1" of 2.500" diameter aluminum

One 1.750" diameter o-ring

Some asphalt car undercoating spray

Cost:

$0.00

Time:

2 hrs

Conclusion:

It works great and finally seals properly

0 comments:

Post a Comment