Replacing an old faded and scratched oil sight glass for the headstock of my metal lathe

Difficulty Level (Easy, Medium, Hard, Insane):

Medium

Process:

The original sight glass for my metal lathe had weathered, corroded and was in such a bad shape that I couldn't even tell whether there was ANY oil in my headstock at all. After carefully measuring the plastic dimensions of the sight glass it came out to be exactly 1/2" wide.

I ordered some 1/2"" Threaded Zinc Air Compressor Oil Level Sight Glasses on eBay just to realize that the 1/2" NPT is actually almost 3/4" wide.

I was debating whether I should order some smaller ones or try to fit the 1/2" sight glasses and decided to try to make it work with the larger ones because I wanted to change the oil in my headstock and really didn't want to wait a few more weeks for the new sight glasses to arrive.

Before I was able to remove the chuck, I had to build a Spindle Lock for my lathe. Once that was done I was able to remove the chuck and get to work on replacing the sight glass.

Before I removed the old sight glass I hauled out my 1/2" NPT tap and did a test hole with threads in a piece of 1/4" steel just to make sure the threads would match up.

After I confirmed that the threads were a match I emptied the oil, broke the old sight glass, and cleaned the headstock. I was doing some research into how to clean the headstock because the oil was so old and sticky and I wanted to make sure I got it really nice and clean. I was concerned that the solvent would break down the new oil so after some investigating I learned that diesel fuel (or kerosene) would work.

I hauled out my syringe, filled it up with diesel and sprayed the inside liberally while reaching into the headstock with a small brush to clean it really good.

Once it was all cleaned, I drilled a 5/8" (or 3/4", I can't remember) hole where the old sight glass was, used the tap to cut the new thread and cleaned out the metal shavings really well. After installing the new oil sight glass I filled it all up with non-detergent oil and I was good to go.

Videos:

Pictures:

|

| Hauling out the lathe to access the rear |

|

| After the oil has been drained and the old sight glass has been removed |

|

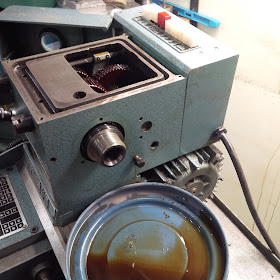

| Another view |

|

| Testing to make sure my 1/2" NPT tap threads would match the sight glass |

|

| A close-up of drilling out the sight glass |

|

| Tapping the hole for 1/2" NPT |

|

| The tapped hole |

|

| Cleaning the headstock with diesel |

|

| A little vinyl tube I stuck in the oil drain hole to drain the diesel fuel properly |

|

| Checking the oil splash guard behind the chuck |

|

| A view of the new sight glass in all its glory |

|

| Another view after the chuck was installed again |

Drill

Drill bits

1/2" NPT tap

Adjustable wrench

Stainless steel bowl

Vinyl hose

Syringe

Spindle Lock

Drill press

Materials:

1/2" oil sight glass

250ml diesel

Non-detergent oil

Cost:

$5.00

Time:

2hrs

Savings:

N/A

Conclusion:

It is so nice to be able to quickly check the oil level

Hello Chris,

ReplyDeleteI have the same problem with the oil sight glass on my Emcomat 8.6..

Before removing the plastic part, which will almost certainly wont come out undamaged, I want to know if it is originally screwed in.

Can you tell me if the original oil glass was screwed in and if so, was it a metric thread?

I hope you can answer my questions and publish them here.

Kind regards,

Hans Hanegraaf

Holland

I can't remember, but in my blog I said that I "broke the old sight glass" so I'm assuming it was pressed in and not screwed.

DeleteOK thank you for responding!

ReplyDelete